the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

experiences and expressions

// MAGAZINE

4 surfaces you thought were impossible to metallize

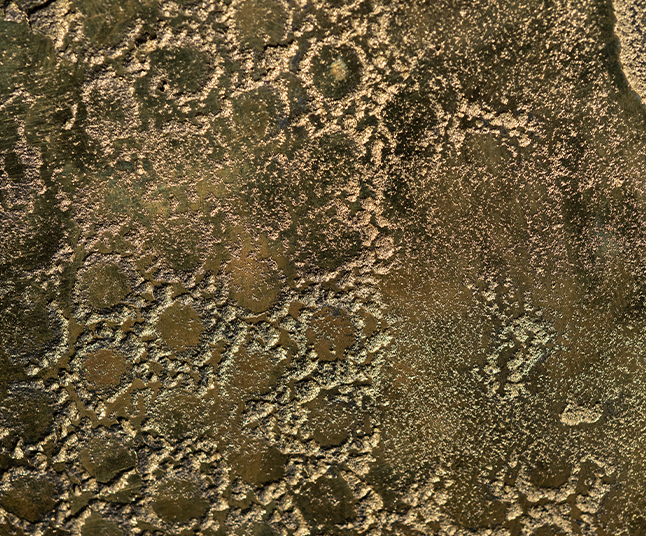

The potential of metallization is almost endless: we are talking about a technique capable of work on surfaces that you thought were impossible to metallize. Not surprisingly, Materica has been betting on it from the very beginning, which is why it studies it day after day with the goal of constantly raising the bar. Because metallization is a constant surprise: it can be applied to unthinkable surfaces, which thanks to it are transformed and get a new life, a new essence.

The metallization of Materica

Before we talk about surfaces, let’s look at what metallization consists of. It originated about 40 years ago as an anticorrosive treatment and then Materica has revolutionized this technique, applying it in the world of architecture and design, art and fashion, enhancing the three-dimensionality of the support to which it is applied. Based on the characteristics and geometry of the object, metallization is able to rework the surface creating something special, unique and different.

The technique: It is done manually by an operator who, with an electric arc gun, melts and projects microparticles of metal wire (copper, bronze, brass, nickel silver, zinc) on the support previously prepared to receive the metal. This application stage is followed by a very onerous and difficult part, that of polishing, which is also done manually. The metal can then be oxidized to obtain different light, color, and reflections.

“Metallizable ” surfaces can be very different from each other:

Metallization on metal

Metallization makes metallic what is not metallic, and can enhance even cold steel, giving it a fine, regal coating. It remains steel, but with a new precious coating of burnished brass. One example is the staircase that Materica worked on and that now dominates an 18th-century palace in the heart of Siena.

Metallization on wood

Wood can be warm but also powerful; it is a surface that offers great opportunities. Opportunities that metallization knows how to seize and emphasize, following its lines, shapes and imperfections: wood is transformed and becomes a precious material, as in Joris Poggioli’s Totem Collection.

Metallization on fabric

Yes, you read that right: even fabric could be metallized, and the result is something that is bound to shock the world of fashion and design. In fact, Materica’s technique is able to process fabrics and textiles, coating them with majesty. Tiziano Guardini’s Kimono is a prime example.

Metallization on resinated polystyrene

In polystyrene is the essence of the phrase “making metallic what is not metallic.” When metallization encounters this surface is capable of completely transforming it, deceiving the mind and perception of the beholder. It is real metal (bronze) but on a digitally printed nylon core Would you tell, for example, looking at the outstanding replica of the Boxer at rest?

Surfaces to be metallized, worlds to be stunned

Metallization thus confirms itself as an extraordinary technique, pushing the design, art and architecture sectors to exploit it and to dare. This is where Materica comes in, which wants to continue to amaze with metallization, enhancing those surfaces that were thought impossible to transform before metallization came along.

experiences and expressions

// MAGAZINE

4 surfaces you thought were impossible to metallize

The potential of metallization is almost endless: we are talking about a technique capable of work on surfaces that you thought were impossible to metallize. Not surprisingly, Materica has been betting on it from the very beginning, which is why it studies it day after day with the goal of constantly raising the bar. Because metallization is a constant surprise: it can be applied to unthinkable surfaces, which thanks to it are transformed and get a new life, a new essence.

The metallization of Materica

Before we talk about surfaces, let’s look at what metallization consists of. It originated about 40 years ago as an anticorrosive treatment and then Materica has revolutionized this technique, applying it in the world of architecture and design, art and fashion, enhancing the three-dimensionality of the support to which it is applied. Based on the characteristics and geometry of the object, metallization is able to rework the surface creating something special, unique and different.

The technique: It is done manually by an operator who, with an electric arc gun, melts and projects microparticles of metal wire (copper, bronze, brass, nickel silver, zinc) on the support previously prepared to receive the metal. This application stage is followed by a very onerous and difficult part, that of polishing, which is also done manually. The metal can then be oxidized to obtain different light, color, and reflections.

“Metallizable ” surfaces can be very different from each other:

Metallization on metal

Metallization makes metallic what is not metallic, and can enhance even cold steel, giving it a fine, regal coating. It remains steel, but with a new precious coating of burnished brass. One example is the staircase that Materica worked on and that now dominates an 18th-century palace in the heart of Siena.

Metallization on wood

Wood can be warm but also powerful; it is a surface that offers great opportunities. Opportunities that metallization knows how to seize and emphasize, following its lines, shapes and imperfections: wood is transformed and becomes a precious material, as in Joris Poggioli’s Totem Collection.

Metallization on fabric

Yes, you read that right: even fabric could be metallized, and the result is something that is bound to shock the world of fashion and design. In fact, Materica’s technique is able to process fabrics and textiles, coating them with majesty. Tiziano Guardini’s Kimono is a prime example.

Metallization on resinated polystyrene

In polystyrene is the essence of the phrase “making metallic what is not metallic.” When metallization encounters this surface is capable of completely transforming it, deceiving the mind and perception of the beholder. It is real metal (bronze) but on a digitally printed nylon core Would you tell, for example, looking at the outstanding replica of the Boxer at rest?

Surfaces to be metallized, worlds to be stunned

Metallization thus confirms itself as an extraordinary technique, pushing the design, art and architecture sectors to exploit it and to dare. This is where Materica comes in, which wants to continue to amaze with metallization, enhancing those surfaces that were thought impossible to transform before metallization came along.

sede principale

Via Guido Rossa,12 Scorzè, 30037, Venezia

sede secondaria

Via dell’Artigianato 1, Trebaseleghe, 35010, Padova

Tel +39 041446351

email: info@materica.eu

P.IVA 03812510273

sede principale

Via Guido Rossa,12 Scorzè

30037, Venezia

Tel +39 041446351

P.IVA 0381251023

// ISCRIVITI ALLA NEWSLETTER

Resta aggiornato su prodotti, news ed eventi.