the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

experiences and expressions

// MAGAZINE

Materica between metallization and sustainability

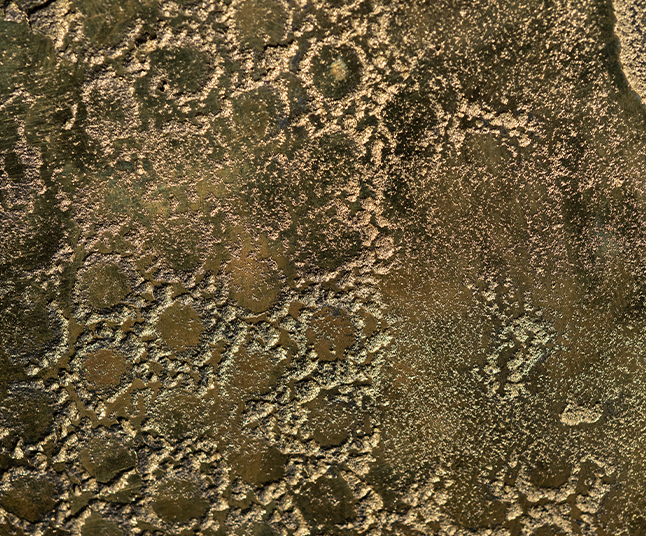

The metallization process of Materica is a revolutionary one that combines aesthetics and quality. The company draws inspiration from alchemy and matter, a combination that plays with surfaces and three-dimensionality, enhanced by the creatives with whom it collaborates, giving rise to unprecedented opportunities in the fields of design, architecture, and art. Thanks to this innovative technique, Materica makes metallic what is not metallic, coating surfaces with metal, even those very different from each other, creating surprising and unique results.

A unique technique

We’re talking about a unique technique, because the applications of Materica’s metallization are virtually endless, since it can work with numerous metals (copper, bronze, brass, nickel silver, zinc) that are projected onto surfaces, such as metal itself, wood, fabric, polystyrene, etc. In doing so, it enhances the support itself on which it is applied and, depending on the characteristics and geometry of the object, the metallization reprocesses it, creating something special and original.

Mastery and sustainability

What sets Materica apart is not only its mastery in metallization but also its deep commitment to environmental sustainability. At the heart of the company’s mission is the responsible use of recycled materials and eco-friendly processes. Materica uses recycled wood and compostable polystyrene, thus reducing the environmental impact of its production. Furthermore, Materica promotes processes aimed at recovering unused raw materials, reducing waste, and contributing to the conservation of natural resources.

Dedication to sustainability

This dedication to sustainability is reflected in every aspect of Materica’s work. From the selection of materials to the design of production processes, the company aims to always reduce environmental impact and promote a greener, more sustainable future. Thanks to this approach, every work produced by Materica is not only an expression of creativity but also a symbol of responsibility, sustainability, and commitment to a better world.

An aesthetic and environmental commitment

In summary, Materica’s processes, especially metallization, are not only innovative techniques but also an expression of commitment to environmental sustainability. Thanks to its dedication to reducing environmental impact and promoting sustainability, Materica stands as a leader in the industry, offering creative and environmentally friendly solutions for contemporary design and art.

experiences and expressions

// MAGAZINE

Materica between metallization and sustainability

The metallization process of Materica is a revolutionary one that combines aesthetics and quality. The company draws inspiration from alchemy and matter, a combination that plays with surfaces and three-dimensionality, enhanced by the creatives with whom it collaborates, giving rise to unprecedented opportunities in the fields of design, architecture, and art. Thanks to this innovative technique, Materica makes metallic what is not metallic, coating surfaces with metal, even those very different from each other, creating surprising and unique results.

A unique technique

We’re talking about a unique technique, because the applications of Materica’s metallization are virtually endless, since it can work with numerous metals (copper, bronze, brass, nickel silver, zinc) that are projected onto surfaces, such as metal itself, wood, fabric, polystyrene, etc. In doing so, it enhances the support itself on which it is applied and, depending on the characteristics and geometry of the object, the metallization reprocesses it, creating something special and original.

Mastery and sustainability

What sets Materica apart is not only its mastery in metallization but also its deep commitment to environmental sustainability. At the heart of the company’s mission is the responsible use of recycled materials and eco-friendly processes. Materica uses recycled wood and compostable polystyrene, thus reducing the environmental impact of its production. Furthermore, Materica promotes processes aimed at recovering unused raw materials, reducing waste, and contributing to the conservation of natural resources.

Dedication to sustainability

This dedication to sustainability is reflected in every aspect of Materica’s work. From the selection of materials to the design of production processes, the company aims to always reduce environmental impact and promote a greener, more sustainable future. Thanks to this approach, every work produced by Materica is not only an expression of creativity but also a symbol of responsibility, sustainability, and commitment to a better world.

An aesthetic and environmental commitment

In summary, Materica’s processes, especially metallization, are not only innovative techniques but also an expression of commitment to environmental sustainability. Thanks to its dedication to reducing environmental impact and promoting sustainability, Materica stands as a leader in the industry, offering creative and environmentally friendly solutions for contemporary design and art.

sede principale

Via Guido Rossa,12 Scorzè, 30037, Venezia

sede secondaria

Via dell’Artigianato 1, Trebaseleghe, 35010, Padova

Tel +39 041446351

email: info@materica.eu

P.IVA 03812510273

sede principale

Via Guido Rossa,12 Scorzè

30037, Venezia

Tel +39 041446351

P.IVA 0381251023

// ISCRIVITI ALLA NEWSLETTER

Resta aggiornato su prodotti, news ed eventi.