the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

the emotion of matter

in the making

the first collection of Materica

elevating substance

experiences and expressions

dialogues and moments

atmosphere

the balance of opposites

to forge, to know, to understand

to mold, to create, to shape

emotion from matter

in the making

the first collection of Materica

to elevate the substance

experiences and expressions

ddialogues and moments

atmosphere

experiences and expressions

// MAGAZINE

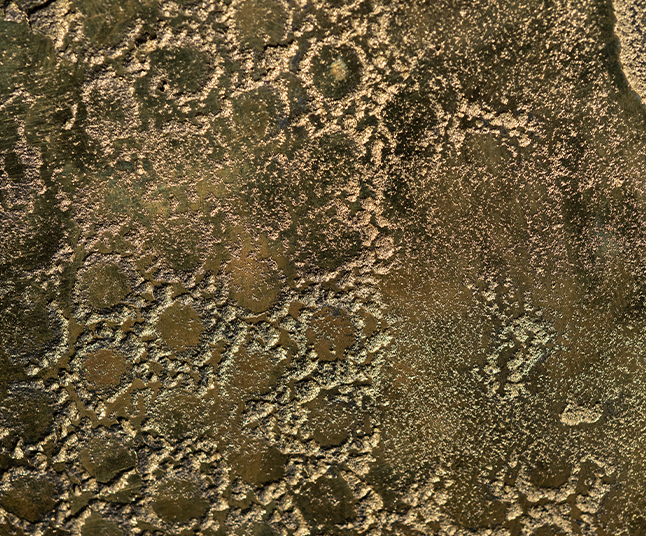

With the metallization of Materica, surfaces are enhanced

Metallization challenges the very essence of an object, redefining its role. It’s an innovative and extraordinary technique that Materica has embraced, developing a unique production process. Initially conceived for anticorrosive purposes, metallization has gradually revealed its true value over time. By reintroducing real metal, it breathes new life and a fresh visual language into numerous types of surfaces, effectively transforming non-metallic materials into metallic ones. Moreover, this technique offers the possibility of further treating the applied metal. How? Oxidizing, coloring, silvering, antiquing, polishing it into a diverse palette of new shades and sensory effects.

The Metallization Technique

Materica’s clear intention is to experiment and offer the market a new way to develop finishes and, consequently, to surprise. While the technique remains singular, the applications of metallization are virtually limitless. This is because it allows for working with various metals (copper, bronze, brass, alpaca, zinc) projected onto vastly different surfaces, such as metal itself, wood, fabric, polystyrene, etc.

The Metallization Process

The metallization process may seem simple, as it involves the melting of metal wires using an electric arc gun: the particles are forcefully projected onto the surface, effectively adorning it with a new layer. Originally conceived for anticorrosive purposes, after years of experimentation, Materica has developed a technique capable of enhancing the three-dimensionality of the support onto which it is applied. Depending on the characteristics and geometry of the object, metallization reprocesses it, creating something special, unique, and new.

The Infinite Possibilities of Materica’s Metallization

It’s evident that this technique opens up aesthetic possibilities that previously required significant efforts (both in terms of production and economically), now more readily exploitable to breathe new life into various sectors. This is confirmed, for example, by several projects that showcase the value of craftsmanship and Materica’s vision, from “The Resting Boxer” to “It’s Not a Simple Stair”, from “Lava Bookcase” to “Interna_mente” (an installation presented at the last Milan Design Week). These extraordinary works are capable of transforming the spaces around them with their aura of prestige and exceptionalism.

experiences and expressions

// MAGAZINE

With the metallization of Materica, surfaces are enhanced

Metallization challenges the very essence of an object, redefining its role. It’s an innovative and extraordinary technique that Materica has embraced, developing a unique production process. Initially conceived for anticorrosive purposes, metallization has gradually revealed its true value over time. By reintroducing real metal, it breathes new life and a fresh visual language into numerous types of surfaces, effectively transforming non-metallic materials into metallic ones. Moreover, this technique offers the possibility of further treating the applied metal. How? Oxidizing, coloring, silvering, antiquing, polishing it into a diverse palette of new shades and sensory effects.

The Metallization Technique

Materica’s clear intention is to experiment and offer the market a new way to develop finishes and, consequently, to surprise. While the technique remains singular, the applications of metallization are virtually limitless. This is because it allows for working with various metals (copper, bronze, brass, alpaca, zinc) projected onto vastly different surfaces, such as metal itself, wood, fabric, polystyrene, etc.

The Metallization Process

The metallization process may seem simple, as it involves the melting of metal wires using an electric arc gun: the particles are forcefully projected onto the surface, effectively adorning it with a new layer. Originally conceived for anticorrosive purposes, after years of experimentation, Materica has developed a technique capable of enhancing the three-dimensionality of the support onto which it is applied. Depending on the characteristics and geometry of the object, metallization reprocesses it, creating something special, unique, and new.

The Infinite Possibilities of Materica’s Metallization

It’s evident that this technique opens up aesthetic possibilities that previously required significant efforts (both in terms of production and economically), now more readily exploitable to breathe new life into various sectors. This is confirmed, for example, by several projects that showcase the value of craftsmanship and Materica’s vision, from “The Resting Boxer” to “It’s Not a Simple Stair”, from “Lava Bookcase” to “Interna_mente” (an installation presented at the last Milan Design Week). These extraordinary works are capable of transforming the spaces around them with their aura of prestige and exceptionalism.

sede principale

Via Guido Rossa,12 Scorzè, 30037, Venezia

sede secondaria

Via dell’Artigianato 1, Trebaseleghe, 35010, Padova

Tel +39 041446351

email: info@materica.eu

P.IVA 03812510273

sede principale

Via Guido Rossa,12 Scorzè

30037, Venezia

Tel +39 041446351

P.IVA 0381251023

// ISCRIVITI ALLA NEWSLETTER

Resta aggiornato su prodotti, news ed eventi.